No products in the cart.

Predetermined Overhead Rate POHR: Formula and Calculation

In contrast, the traditional allocation method commonly uses cost drivers, such as direct labor or machine hours, as the single activity. Commonly, the manufacturing overhead cost for machine hours can be ascertained from the predetermined overhead rate in the manufacturing industry. Further, it is stated that the reason for the same is that overhead is based on estimations and not the actuals. In simple terms, it’s a kind of allocation rate that is used for estimated costs of manufacturing over a given period. It’s a good way to close your books quickly, since you don’t have to compile actual manufacturing overhead costs when you get to the end of the period. Keep reading to learn about how to find the predetermined overhead rate and what this means.

- In simple terms, it’s a kind of allocation rate that is used for estimated costs of manufacturing over a given period.

- In the absence of predetermined overhead rates, the business cannot compare actual expenses with any standard and, thus, cannot evaluate its actual performance.

- A Predetermined Overhead rate shall be used to calculate an estimate on the projects that are yet to commence for overhead costs.

- This activity base is often direct labor hours, direct labor costs, or machine hours.

- The overhead cost per unit from Figure 6.4 is combined with the direct material and direct labor costs as shown in Figure 6.3 to compute the total cost per unit as shown in Figure 6.5.

AP & INVOICE PROCESSING

Suppose GX company uses direct labor hours to assign manufacturing overhead cost to job orders. The company’s budget shows an estimated manufacturing overhead cost of $16,000 for the forthcoming year. The company estimates that 4,000 direct labors hours will be worked in the forthcoming year.

Multiple or departmental predetermined overhead rates:

- One of the advantages of predetermined overhead rate is that businesses can use it to help with closing their books more quickly.

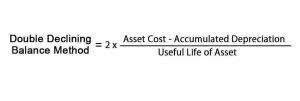

- A predetermined overhead rate is defined as the ratio of manufacturing overhead costs to the total units of allocation.

- Remember, even a rough predetermined rate is better than ignoring overhead entirely, which is a common mistake that leads to underpricing and cash flow problems.

- Until now, you have learned to apply overhead to production based on a predetermined overhead rate typically using an activity base.

- If the actual amount of overhead is different from the estimated amount used, the overhead is considered either over-absorbed or under-absorbed.

- One common way to adjust for over or under-absorption is to adjust your cost of goods sold for the difference.

Therefore, the business must use a predetermined overhead rate to budget its expenses for the future. One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate. A business can calculate its actual costs periodically and then compare that to the predetermined overhead rate in order to monitor expenses throughout the year or see how on-target their original estimate was. This comparison can be used to monitor or predict expenses for the next project (or fiscal year). Using the predetermined overhead rate formula and calculation provides businesses with a percentage they can monitor on a quarterly, monthly, or even weekly basis.

Example 2: Cost per Hour

Added to these issues is the nature of establishing an overhead rate, which is often completed months before being applied to specific jobs. Establishing the overhead allocation rate first requires management to identify which expenses they consider manufacturing overhead and then to estimate the manufacturing overhead for the next year. Manufacturing overhead costs include all manufacturing costs except for direct materials and direct labor. Estimating overhead costs is difficult because many costs fluctuate significantly from when the overhead allocation rate Mental Health Billing is established to when its actual application occurs during the production process.

- At a later stage, when the actual expenses are known, the difference between that allocated overhead and the actual expense is adjusted.

- At the end of the accounting period, you’ll have a difference (called a variance) between your applied overhead (using the predetermined rate) and your actual overhead costs.

- That is, a predetermined overhead rate includes the ratio of the estimated overhead costs for the year to the estimated level of activity for the year.

- For some companies, the difference will be very minute or there will be no difference at all between different basis while for some other companies the differences will be significant.

- With $2.00 of overhead per direct hour, the Solo product is estimated to have $700,000 of overhead applied.

However, if you experience significant changes in your operations or costs, you might want to recalculate mid-year. For example, if you add a new production facility, experience dramatic changes predetermined oh allocation rate in utility costs, or significantly change your production methods, it makes sense to revisit your overhead rate. By leveraging Flxpoint’s comprehensive platform, businesses can effectively reduce overhead costs, leading to improved profitability and operational efficiency.

Building on the Accounting Foundation of the External Financial Statements

Just-in-time systems also allow you to produce items when ordered rather than in preparation for an order, eliminating both work-in-progress and an overabundance of finished goods that have not been sold. This is done by determining the number of hours the machine was used over the last quarter. Create a Full Dynamic Financial Model in 2 Days (6 hours) | Any Graduate Or Professional is eligible | Build & Forecast IS, BS, CF from Scratch. B2C usually involves https://heliosgaming.fr/2022/02/11/solved-what-is-the-difference-between-expense/ more picking and packing time for smaller orders, while B2B might have more equipment usage for bulk orders. If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

- The choice of selecting any absorption basis depends on the judgment and common sense; especially depends on the type of the manufacturing activities.

- Allocating overhead costs uses the same calculation as the overhead rate, with the results used differently.

- The most prominent concern of this rate is that it is not realistic being that it is based on estimates.

- For example, if you have both a cutting department with expensive machinery and a hand-finishing department that’s labor-intensive, you might use machine hours for the first and direct labor hours for the second.

- After going to its terms and conditions of the bidding, it stated the bid would be based on the overhead rate percentage.

Since predetermined overhead rates are used in budgets, they can also act as a monitoring and controlling tool for businesses. When monitoring and controlling overheads, businesses need some standard, to compare actual overheads with, to understand whether the budget is being properly followed. In the absence of predetermined overhead rates, the business cannot compare actual expenses with any standard and, thus, cannot evaluate its actual performance. The formula for a predetermined overhead rate is expressed as a ratio of the estimated amount of manufacturing overhead to be incurred in a period to the estimated activity base for the period. Take, for instance, a manufacturing company that produces gadgets; the production process of the gadgets would require raw material inputs and direct labor.